In recent years, the company has been committed to the development of new products, and has successively introduced all kinds of low-smoke halogen-free flame-retardant power cables, low-smoke halogen-free fire-resistant power cables, rodent-proof and termite-proof cables, etc., so that the company's products are more in line with market demand.

The search for history.Erase all records.

- All

- Product Management

- News

- FAQ

Address: Economic Development Zone, Yin Village, Renqiu City, Cangzhou, Hebei Province

Telephone:+86-317-2270599

Custom Message

Our staff will contact you within 24 hours (working days). If you need other services, please call the service hotline: wei@huachencable.cn

Control Cable

Classification:

Control Cable

Technical Support:

E-mail:

Key words.:

Product Description

1. Product implementation standards

This product implements 9330-2008 and corporate standards.

The flame retardant properties meet the requirements of GB/T19666-2005 and GA306.1-2007.

2. Product features and uses

Cross-linked polyethylene, PVC insulated and sheathed control cables have good corrosion resistance to chemical solvents. It is suitable for connecting wires of electrical appliances and instruments with AC rated voltage (U0/U) and below 450/750V and transmission lines of automation systems in petroleum, chemical, electric power, metallurgical and other enterprises.

3. Use characteristics

①AC rated voltage: (U0/U) 450/750V

②Long-term allowable working temperature of cable conductor:

Polyvinyl chloride insulated cable 70℃, 90℃, 105℃ (according to the temperature resistance grade of the model)

Low-smoke halogen-free flame-retardant cable 70℃

③ The lowest ambient temperature: PVC insulation and sheath: fixed laying: -40℃, non-fixed laying -15℃

④ Installation and laying temperature: PVC sheathed cable is not lower than 0℃

⑤ The recommended allowable bending radius for laying: copper tape shielded or steel wire steel tape wound armored cable should not be less than 12 times the outer diameter of the cable, and cables of other structures should not be less than 6 times the outer diameter of the cable.

4.The main technical parameters

|

item |

unit |

technical parameter |

|||||||||

| DC resistance of conductor at 20℃≤ | Ω/Km | section | 0.75 | 1 | 1.5 | 2.5 | |||||

| Coating | Not tinned | Tinned | Not tinned | Tinned | Not tinned | Tinned | Not tinned | Tinned | |||

| 1、2kind | 24.5 | 24.7 | 18.1 | 18.2 | 12.1 | 12.2 | 7.41 | 7.56 | |||

| 5kind | 26 | 26.7 | 9.5 | 20 | 13.3 | 13.7 | 7.98 | 8.21 | |||

| Insulation resistance at the highest allowable temperature of the cable≥ | MΩ/Km | PVC | 1 kind | 0.012 | 0.011 | 0.011 | 0.01 | ||||

| 2、5 kind | 0.011 | 0.01 | 0.01 | 0.009 | |||||||

| Polyethylene insulation | 1 | ||||||||||

| XLPE insulation | 1 | ||||||||||

| Test voltage | KV/5min | 3 | |||||||||

| Flame retardant properties | Class A or Class B (test according to GB/T18380.3 standard) | ||||||||||

5.Product model and name

|

model |

product name |

| KVV | Copper core PVC insulated and sheathed control cable |

| KVVR | Copper core PVC insulated and sheathed soft control cable |

| KVV22 | Copper core PVC insulated and sheathed steel tape armored control cable |

| KVV32 | Copper core PVC insulated and sheathed thin steel wire armored control cable |

| KVVP | Copper core PVC insulated and sheathed copper wire braided shielded control cable |

| KVVRP | Copper core PVC insulated and sheathed copper wire braided shielded soft control cable |

| KVVP3 | Copper core PVC insulated and sheathed aluminum-plastic composite tape wrapped shielded control cable |

| KVVRP3 | Copper core PVC insulated and sheathed aluminum-plastic composite tape wrapped shielding soft control cable |

| KVVP2 | Copper core PVC insulated and sheathed aluminum-plastic composite tape wrapped shielded soft control cable |

| KVVRP2 | Copper core PVC insulated and sheathed copper-plastic composite tape wrapped shielded control cable |

| KVV22 | Copper core PVC insulated and sheathed copper-plastic composite tape wrapped shielded soft control cable |

| KVVP2-22 | Copper core PVC insulated and sheathed copper wire braid shielded steel tape armored control cable |

| NH-KVV | Copper core PVC insulated and sheathed copper-plastic composite tape wrapped shielded steel tape armored control cable |

| NH-KVVR | Copper core PVC insulated and sheathed fire-resistant control cable |

| WDZC-KEE | Copper core PVC insulated and sheathed fire-resistant flexible control cable |

| WDZC-KEEP | Copper core low-smoke halogen-free polyolefin insulated and sheathed control cable |

| WDZC-KEER | Copper core low-smoke halogen-free polyolefin insulated and sheathed copper wire braided shielded control cable |

| WDZC-KEERP | Copper core low-smoke halogen-free polyolefin insulated and sheathed control soft cable |

| KYJV | Copper core low-smoke halogen-free polyolefin insulated and sheathed copper wire braided shielded control soft cable |

| KYJVR | Copper core XLPE insulated PVC sheathed control cable |

| KYJVP | Copper core XLPE insulated PVC sheathed control soft cable |

| KYJVRP | Copper core XLPE insulated PVC sheathed control cable |

| KYJV22 | Copper core XLPE insulated PVC sheathed copper wire shielded control soft cable |

| KYJVP22 | Copper core XLPE insulated PVC sheathed steel tape armored control cable |

Note: Flame retardant grades are divided into three grades: A, B, and C

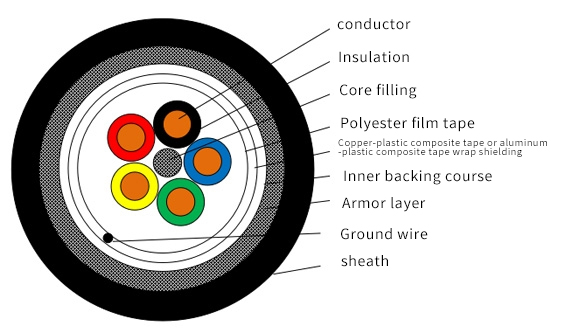

6. Product structure

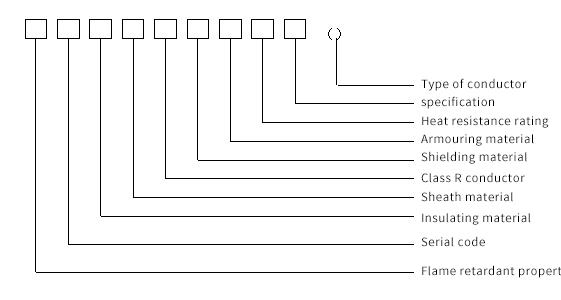

7. Model description

8. Code name and meaning

|

item |

code |

Code meaning |

| Flame retardant properties | / | Non-flame retardant can be omitted |

| ZA | Class A flame retardant | |

| ZB | Class B flame retardant | |

| ZC | Class C flame retardant | |

| WDZC | Low-smoke halogen-free flame retardant | |

| WDZN | Low-smoke and low-halogen refractory | |

| Series code | K | Control Cable |

| Insulation Materials | V | Polyvinyl chloride |

| YJ | XLPE | |

| F | Fluoroplastic | |

| G | Silicone Rubber | |

| E | Polyolefin | |

| Sheath material | V | Polyvinyl chloride |

| E | Polyolefin | |

| G | Silicone Rubber | |

| F | Fluoroplastic | |

| Shielding material | P | Copper wire or tinned copper wire braid |

| P3 | Aluminum-plastic composite tape | |

| P2 | Copper-plastic composite tape | |

| Armor material | 22 | Wrapping steel tape armored PVC sheath |

| 32 | Winding steel wire armored PVC sheath | |

| Heat resistance grade | 70 | Maximum working temperature 70℃ (can be omitted) |

| 90 | Maximum working temperature 90℃ | |

| 105 | Maximum working temperature 105℃ | |

| 180 | Maximum working temperature 180℃ | |

| Conductor type | 1 kind | Single stranded conductor |

| 2 kind | 7 stranded conductor | |

| 5 kind | Stranded conductor | |

| standard | Number of cores╳Nominal cross-section of conductor |

Previous

Next

Related Products

Message consultation

Our staff will contact you within 24 hours (working days). If you need other services, please call the service hotline: wei@huachencable.cn

7*24h

24-hour online service

Telephone: +86-317-2270599

+8613911899055、+8613901289110

Mailbox:wei@huachencable.cn

Address: South of Yin Village, Majiawu Town, Renqiu City, Cangzhou City, Hebei Province